Linear vs Switching Power Supply: Understanding the Differences

This article delves into the core concepts of linear vs switching power supply, exploring their efficiency, noise levels, and other key factors, that help make the right choice for your projects!

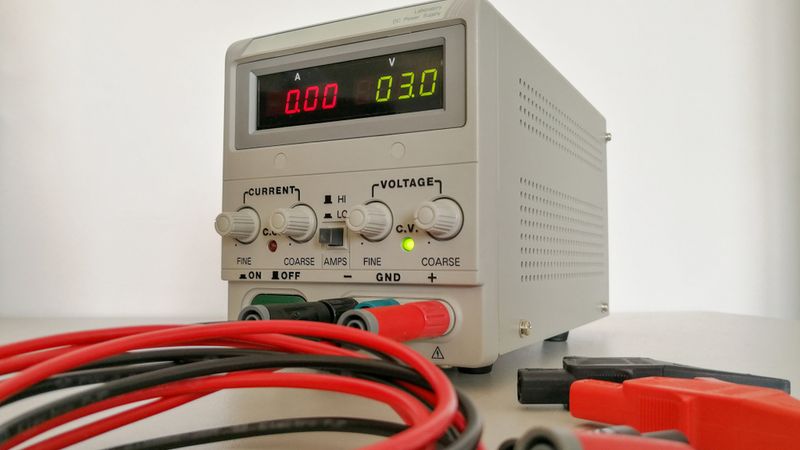

Precise Variable Voltage (V) and Current (I) Power Supply used in Prototyping

Introduction

Power supplies, or PSUs, are essential components in electronic devices, converting raw AC power into usable DC voltage. The debate between two primary types: linear vs switching power supply has long been a central topic for engineers and designers aiming to optimize their systems. While linear power supplies offer simplicity and low-noise output, switching power supplies excel in efficiency and compactness.

Understanding the differences between linear vs switching power supply is essential for selecting the right solution for specific applications. This article explores the basics, key distinctions, advantages, and limitations of linear vs switching power supply!

Dive into the Basics: Understanding Power Supply Mechanics

Principles of Operation

Switching and linear power supplies cater to distinct electronic needs handling energy in ways that directly affect the performance and suitability of end-use applications. Each type operates on unique principles that make them suitable for specific scenarios.

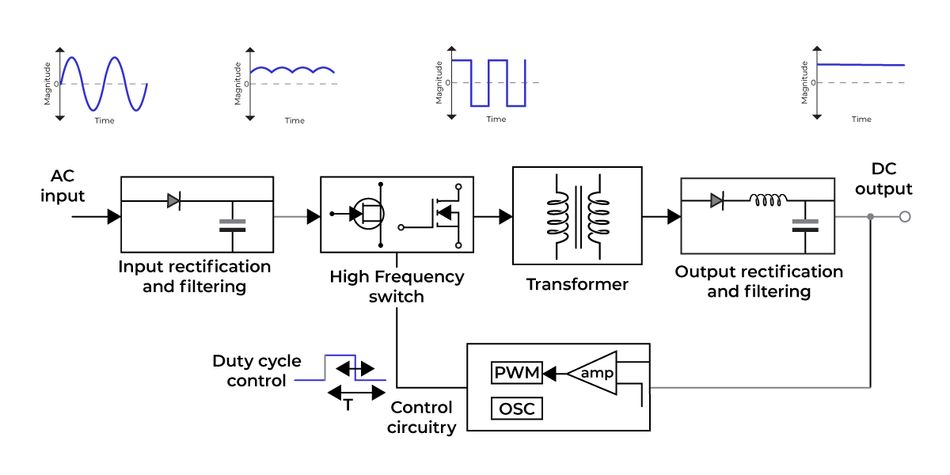

Switching Power Supplies: Operate using high-frequency switching transistors to convert power efficiently. By toggling the input power on and off rapidly, these supplies maintain high efficiency, often exceeding 90%. [1] This is achieved through mechanisms like pulse width modulation (PWM), which precisely controls the energy delivered to the output. Such efficiency is critical in energy-intensive environments like data centers, where reducing operational costs and managing heat dissipation are paramount.

SMPS are commonly employed in applications requiring compact designs, such as portable electronics, LED lighting systems, and telecom equipment. Their capability to handle wide input voltage ranges while delivering stable DC output voltage makes them versatile in modern power supply design.

Linear Power Supplies: Regulate output voltage by dissipating excess power as heat through components like linear regulators or MOSFETs. They provide a stable, noise-free DC voltage, which is essential for sensitive applications.

Their simple design inherently produces minimal electromagnetic interference (EMI), making them ideal for environments requiring precise voltage regulation and low noise levels. This includes applications related to high-fidelity audio systems or laboratory test benches. However, their efficiency is lower compared to SMPS, especially when dealing with high power or high voltage requirements, where significant energy is lost as heat.

Component Analysis

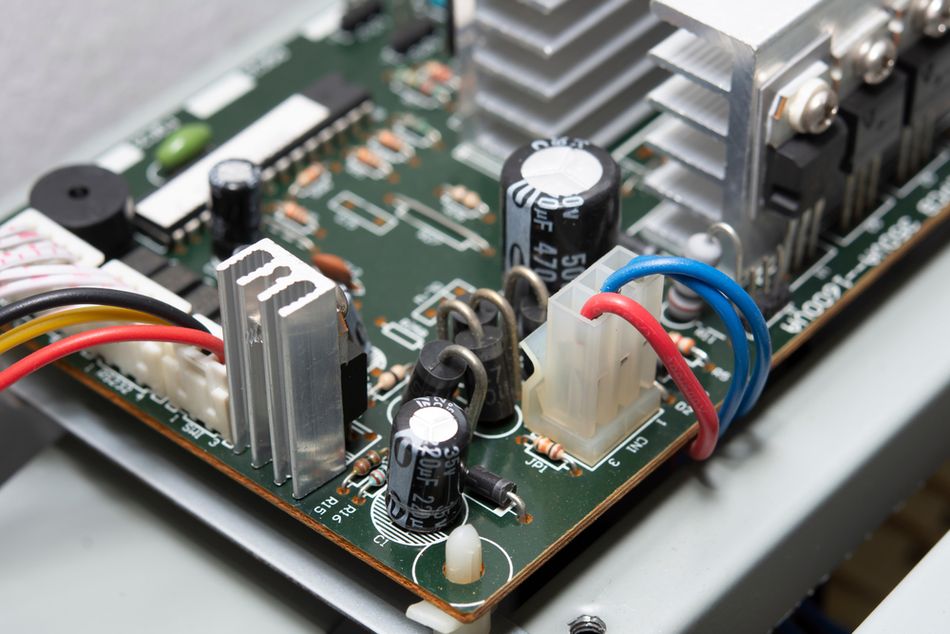

The performance, efficiency, and reliability of power supplies depend heavily on the design and selection of critical components such as transformers, capacitors, op-amps, and rectifiers. These components form the backbone of any type of power supply and must be carefully chosen based on the intended application.

1. Transformers:

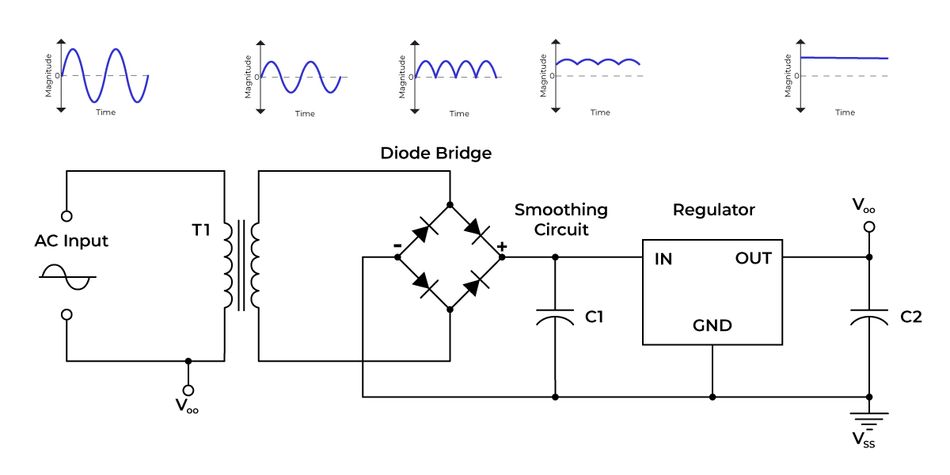

Linear Supplies: Transformers in linear designs are typically large and heavy, as they must operate at the mains AC voltage frequency (50/60 Hz) to deliver the required power. These transformers are critical in industrial control systems, where sustained heavy loads and reliability are priorities.

Switching Supplies: In contrast, SMPS transformers are compact, operating at high-frequency switching rates. This allows them to handle the same power levels with significantly reduced size and weight, a vital characteristic for portable electronics and space-constrained designs.

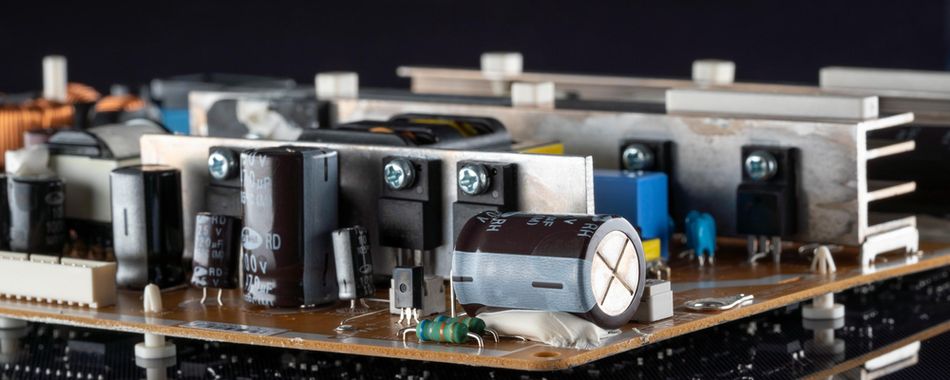

2. Capacitors:

Linear Supplies: These systems rely on high-capacitance electrolytic capacitors to stabilize voltage and filter ripple effectively. This ensures consistent performance in devices like medical imaging equipment or audio amplifiers.

Switching Supplies: SMPS often use ceramic or film capacitors, which offer faster charge and discharge rates. [2] This supports dynamic loads and quick power adjustments in applications like consumer electronics and IoT devices.

3. Rectifiers:

In linear supplies, rectifiers are employed to convert alternating current (AC) to direct current (DC), handling sustained loads efficiently. This is usually seen in telecommunication systems and critical infrastructure setups.

SMPS rectifiers are optimized for high-speed operation and minimal losses, ensuring the high efficiency necessary for modern computing hardware. In these applications, balancing performance with thermal management is a critical consideration.

4. Semiconductors:

High-performance switching transistors and diodes now allow for less heat generation and higher efficiency, enabling smaller, lighter designs without compromising functionality. These innovations have become useful in DC power supply units for mobile computing, automotive systems, and industrial automation.

By understanding the circuitry and components that define each power supply type, engineers can design systems tailored to specific requirements. The choice of components like heat sinks, control circuits, and rectifiers directly impacts the functionality and lifespan of the power supply.

Recommended Reading: Power Management for Tomorrow’s Innovations

Advantages, Limitations, and Working Explained

Linear Power Supply

Linear power supplies operate by stepping down the input voltage to a desired level using a transformer, followed by a rectifier to convert AC power to DC voltage. The resulting DC output, however, may still have ripples. To address this, the voltage is filtered using capacitors to smooth out fluctuations. Finally, a linear regulator fine-tunes the output, ensuring a stable and clean DC output voltage.

Advantages of Linear Power Supplies:

1. Low Noise Levels:

Linear supplies are known for their exceptionally clean and stable output, making them ideal for analog devices and applications.

2. Simple Design:

Their straightforward design reduces the complexity of the control circuit and makes them easier to maintain.

3. Reliable Operation:

The lack of high-frequency switching results in fewer electromagnetic interference (EMI) issues, ensuring compatibility with sensitive systems.

Limitations of Linear Power Supplies:

1. Low Efficiency:

Linear supplies dissipate excess energy as heat, which leads to significant energy loss, especially in high-power applications.

2. Bulkier Components:

The reliance on large ferrite core transformers and heat sinks contributes to their larger size and weight.

3. Limited Application Range:

They are less suitable for applications requiring high efficiency or compact designs, such as portable devices.

Switching Power Supply

Switching power supplies (SMPS), or switchers use high-frequency switching transistors to convert power. Unlike linear supplies, SMPS chop the input volts at high speeds using techniques like pulse width modulation (PWM). This process allows for efficient transformation and regulation of DC output.

Advantages of Switching Power Supplies:

1. High Efficiency:

SMPS achieve efficiencies exceeding 90%, making them suitable for energy-intensive applications like data centers and telecom systems.

2. Compact Design:

The use of smaller, high-frequency transformers and miniaturized components makes SMPS ideal for devices where space is a constraint, such as smartphones and IoT devices.

3. Wide Input Voltage Range:

SMPS can handle variable input voltages, enabling their use in diverse power applications across industries.

Limitations of Switching Power Supplies:

1. EMI Concerns:

The high-frequency operation can generate electromagnetic interference, requiring additional filtering components.

2. Complex Design:

Advanced circuitry and semiconductor components make SMPS more expensive to manufacture and harder to repair.

3. Noise Levels:

SMPS may produce electrical noise, limiting their use in certain analog applications.

Here’s a table of the key differences between linear and switching power supplies:

| Aspect | Linear Power Supply | Switching Power Supply (SMPS) |

| Efficiency | Typically low, with significant heat loss | High, often exceeding 90% |

| Size and Weight | Larger due to heavy transformers and heat sinks | Compact, owing to high-frequency transformers |

| Noise Levels | Minimal, ideal for sensitive applications | Higher, requires additional filtering |

| Cost | Lower initial cost, higher operational cost | Higher initial cost, lower operational cost |

| Applications | Audio systems, medical devices, lab equipment | Telecom, data centers, portable electronics |

Recommended Reading: EMI Shielding: Protecting Electronic Devices in a Noisy World

Cutting-Edge Innovations in Power Supply Technology

Efficiency Enhancements

Advancements in power supply technology have revolutionized efficiency, largely driven by innovations such as Pulse-Width Modulation (PWM). [3] Originally developed to optimize amplifier efficiency, PWM reduces idle time and minimizes energy wastage by dynamically modulating the pulse width of the output voltage. Today, PWM is central to numerous applications, from DC power supplies in consumer electronics to switch mode power supplies (SMPS) in industrial systems.

In practical terms, modern computer power supplies, electric vehicles, and renewable energy systems PWM optimize power distribution. This effectively ensures that only the necessary amount of energy is expended. This not only conserves energy but also helps in cutting down operational costs and lessening environmental impact due to reduced power consumption.

Furthermore, the efficiency gains from PWM technology contribute to improved overall system performance. By limiting power loss as heat, PWM allows electronic devices to operate at lower temperatures, enhancing their stability and extending their operational lifespans. For environments such as data centers, the increased efficiency and output stability enabled by PWM are critical.

Future advancements in PWM circuitry are expected to yield even higher efficiency levels, contributing to sustainable energy practices and enhanced performance in diverse applications. This includes industrial automation, electric vehicle chargers, and smart power grids.

Size and Heat Management

Modern power supply design is increasingly focused on reducing size and improving heat management, addressing critical challenges in compact, high-performance electronics. Through breakthroughs in material science and thermal engineering, engineers are achieving remarkable improvements in energy efficiency and thermal control.

Innovative materials like silicon carbide (SiC) and gallium nitride (GaN) have dramatically enhanced thermal performance. These materials are commonly used in high-frequency switching in data centers, DC voltage converters in electric vehicles, and low-voltage power supplies for wearable technology. Their superior thermal conductivity and electrical efficiency reduce noise levels and improve operational stability under heavy loads.

To further support compact designs, miniaturized components and optimized PCB layouts are being integrated into devices such as smartphones, IoT adapters, and wearables. Cooling strategies like liquid cooling systems and advanced airflow management ensure effective heat dissipation. This enables devices to maintain high performance without overheating.

These advancements also cater to high-power applications, such as industrial equipment and amplifiers, where maintaining a balance between compactness and thermal efficiency is critical. For instance, rectifiers in power supplies for telecom systems now combine compact designs with enhanced cooling to manage sustained workloads efficiently.

By leveraging these materials, designs, and solutions, engineers are creating power supplies that are smaller, more reliable, and capable of meeting the growing demands of modern electronics. This continuous innovation supports the development of devices that are not only energy-efficient but also sustainable and user-friendly.

Recommended Reading: Rectifier Diode: Revolutionizing Electrical Applications with Advanced Semiconductor Technology

Navigating the Pitfalls: Challenges in Power Supply Design

Reliability Concerns

Reliability remains a cornerstone in the design and operation of both switching power supplies (SMPS) and linear supplies. Challenges such as thermal stress, voltage drops, and component degradation can significantly impact the operational lifespan and efficiency of a DC power supply. To mitigate these issues, advanced materials like silicon carbide (SiC) and gallium nitride (GaN) are increasingly used. These materials not only offer superior thermal conductivity but also provide exceptional electrical durability. This makes them ideal for applications requiring high-voltage handling and low-voltage regulation.

One of the key metrics in reliability assessment is the Mean Time Between Failures (MTBF). SMPS typically exhibit higher MTBF values due to their solid-state designs that lack moving parts, reducing mechanical wear. [4] This characteristic is critical in industrial processes, where prolonged uptime is essential to maintain operational continuity. Understanding MTBF ratings allows engineers to forecast maintenance schedules, minimizing disruptions in systems like critical infrastructure or automotive production lines.

Additional factors, such as efficient heat dissipation through heat sinks and improved control circuits, further enhance the reliability of modern power sources. By incorporating rectifiers and advanced semiconductor technologies, engineers can significantly extend the life of power supply units. These advancements not only increase the lifespan of power supplies but also deliver measurable returns on investment, particularly in high-reliability applications.

Cost vs Performance

Balancing cost and performance in power supply design is a critical consideration, particularly when evaluating types of power supplies such as switching versus linear.

SMPS, while more expensive to manufacture due to their complex circuitry, high-quality transistors, and control software, offer enhanced high efficiency and lower operational costs over time. They are ideally suited for high-power and real-time applications, such as telecommunication networks, where their energy savings justify the higher upfront investment.

On the other hand, linear power supplies, with their simpler designs and low-cost manufacturing, often incur higher operational costs due to less efficient power conversion. They remain a popular choice for analog systems, such as amplifiers and medical imaging equipment, where low noise levels and precise voltage regulation are critical. These supplies also avoid complex feedback control mechanisms, making them easier to maintain in local controllers and field sites.

Trade-offs between these power supply types must be carefully assessed. In budget-sensitive scenarios, such as consumer-grade adapters or chargers, linear power supplies may provide sufficient performance. However, in applications demanding high-frequency switching, higher efficiency, and compact designs, SMPS is the preferred choice.

Engineers must also consider cybersecurity vulnerabilities in modern industrial applications, as more advanced SMPS designs incorporate connectivity for remote monitoring and control. This feature, while beneficial, adds to the complexity and cost of SMPS. By aligning technical specifications with production processes and supply chain considerations, professionals can achieve optimal performance and cost-effectiveness in their designs.

Ultimately, the choice between SMPS and linear power supplies depends on the specific needs of the application. This includes factors like input voltage, output voltage, environmental constraints, and long-term operational goals. Through careful evaluation, engineers can make informed decisions that balance performance, reliability, and cost.

Recommended Reading: Qoitech for Power Analysis and Battery Optimisation

Conclusion

Switching power supplies, with their high efficiency and advanced heat management capabilities, are suited for environments where power density and long-term operational costs are critical. Conversely, linear power supplies, favored for their simplicity and exceptional noise suppression, remain indispensable in applications where precision and reliability are critical.

Ongoing advancements in materials science and electronic regulation continue to push the boundaries of what these technologies can achieve. This evolving landscape actively contributes to shaping the next generation of power solutions that align with global sustainability goals. By leveraging this knowledge, professionals can enhance their capacity to innovate and make impactful decisions that optimize performance and cost-efficiency.

Frequently Asked Questions

1. What is the difference between a linear and a switching power supply?

A. The main difference lies in how they convert and regulate power. Linear power supplies use transformers and regulators to produce a stable DC output voltage with low noise but lower efficiency. Switching power supplies (SMPS) rely on high-frequency switching for greater efficiency, compact size, and adaptability to varying loads, but they may generate more electromagnetic interference (EMI).

2. Which is more efficient: linear or switching power supply?

A. Switching power supplies are significantly more efficient, often exceeding 90%, due to their ability to minimize energy loss as heat. Linear power supplies, while less efficient, are preferred for noise-sensitive applications like audio amplifiers and medical devices.

3. Where are linear power supplies used?

A. Linear power supplies are commonly used in applications requiring clean and stable power, such as audio systems, medical equipment, and test and measurement devices.

4. Why are switching power supplies better for compact devices?

A. Switching power supplies utilize high-frequency transformers and advanced semiconductors, enabling them to deliver high efficiency in a smaller form factor. This makes them ideal for compact devices like smartphones, laptops, and IoT gadgets.

5. How do I choose between a linear and switching power supply?

A. The choice depends on your application! Use a linear power supply for low noise levels and simple design needs, such as in analog devices. Opt for a switching power supply for high-efficiency requirements, compact designs, or high-power applications like telecommunications or industrial automation.

References

[1] MPS. Uses, Advantages, and Working Principles of a Switching Power Supply [Cited 2024 December 10] Available at: Link

[2] SAE. Choosing a Capacitor for Use as a Switch-Mode Power Supply Filter [Cited 2024 December 10] Available at: Link

[3] Eledge. PWM Pulse Technology: Key Control Method in the Field of New Energy [Cited 2024 December 10] Available at: Link

[4] TDK. How to Improve Power Supply MTBF and Reliability [Cited 2024 December 10] Available at: Link

Table of Contents

IntroductionDive into the Basics: Understanding Power Supply MechanicsPrinciples of OperationComponent AnalysisAdvantages, Limitations, and Working ExplainedLinear Power SupplySwitching Power SupplyCutting-Edge Innovations in Power Supply TechnologyEfficiency EnhancementsSize and Heat ManagementNavigating the Pitfalls: Challenges in Power Supply DesignReliability ConcernsCost vs PerformanceConclusionFrequently Asked QuestionsReferences