Solving Automotive Motor Control for Electric Vehicles

As the number of motors in cars increases, so does the need for elegant and comprehensive control solutions.

This is the fourth article in a 5-part series exploring the future of mobility. The series looks into which technologies enable rapid advancements in the efficiency, safety, and power of the vehicles of tomorrow. The series looks into which technologies are enabling the necessary rapid advancements in efficiency, safety, and power. This series is sponsored by Mouser Electronics, an online distributor of electronic components. Through their sponsorship, Mouser Electronics is dedicated to supporting a future of connected and efficient mobility.

Introduction

Automotive motor control is a principal concern in electric vehicles due to its potential to provide more services with reduced size motors and minimize energy consumption. At present, premium segment Electric Vehicles (EVs) are fitted with more than 60 motors, which continues to grow. The movement toward electric cars creates a myriad of opportunities for innovation as components, and parts can be updated and optimized for every new generation of vehicles. As manufacturers aim to quench the consumers’ constant thirst for connectivity, the higher amounts of functionality and automated features generate the need for an elegant and comprehensive control solution. The enhancements introduced with the 48V bus highlight the motor control challenges and the broad expertise needed to control vehicle motor types.

Types and Applications of Electric Motors

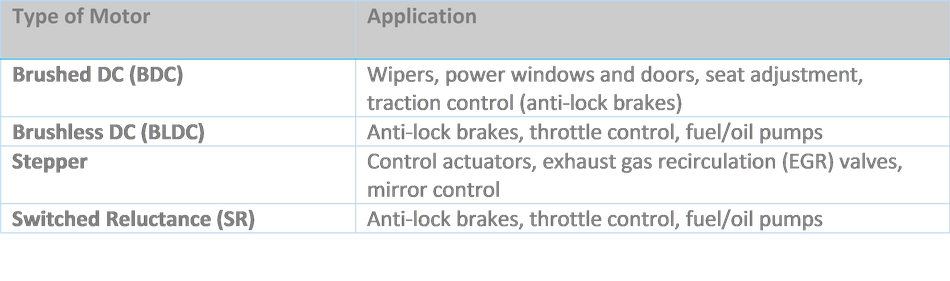

Electric motors have several relevant types. Each has its own set of applications within the vehicle. Table 1 shows four different types of motors and the vehicle application in which the motor can be found:

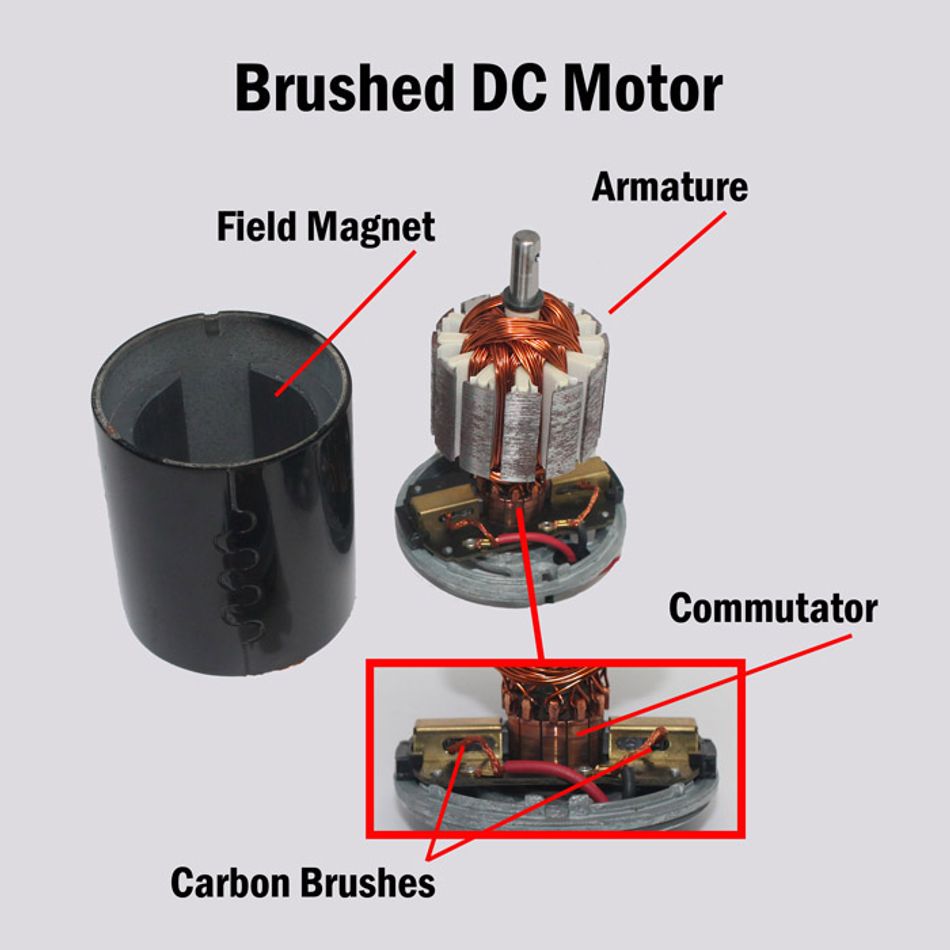

Brushed DC (BDC): With speed and torque proportional to the applied voltage and current, brushed DC motors are a straightforward control solution. As a result, engineers select BDC for diverse applications within the vehicle.

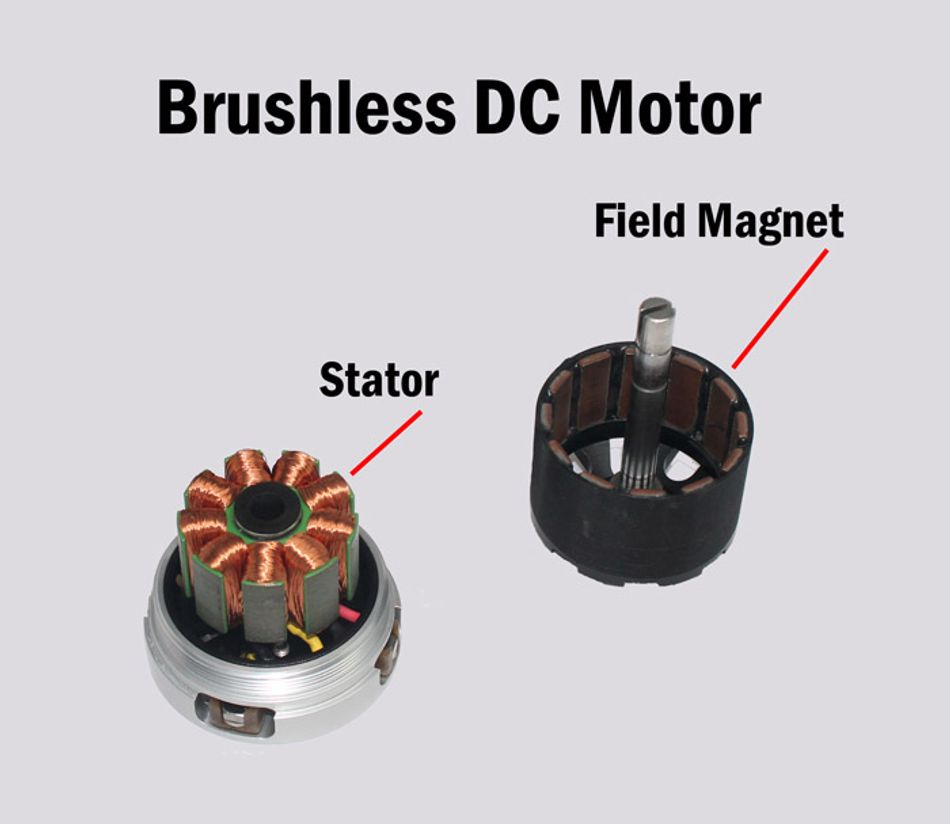

Brushless DC (BLDC): Like BDC in torque and speed performance, the brushless form offers a high power-to-size ratio. This property lends the BLDC to applications with distinct load conditions that are far apart. As an example, ABS engages only when the brake is depressed hard. Throttling and pumping applications rapidly change pressure from high to low. The high power-to-size ratio also improves BLDC’s efficiency.

Stepper: While brushed and brushless DC motors focus on macro functions such as stopping the vehicle and operating pumps, stepper motors focus on precision applications such as mirror position, opening or closing the EGR valve, or regulating speed during idling. Due to requiring near-infinite control within the range, stepper motor control is defined by the motor’s construction, aiming to provide near-infinite steps for use as set points.

Figure 3 Stepper Motor for automobile applications (2)

Switched Reluctance (SR): Like brushless DC, SR motor applications are high-speed and power-dense. Because they do not contain permanent magnets, SR motors provide efficient, high-speed action at a reduced packaging size.

Spotlight Application: 48V Bus

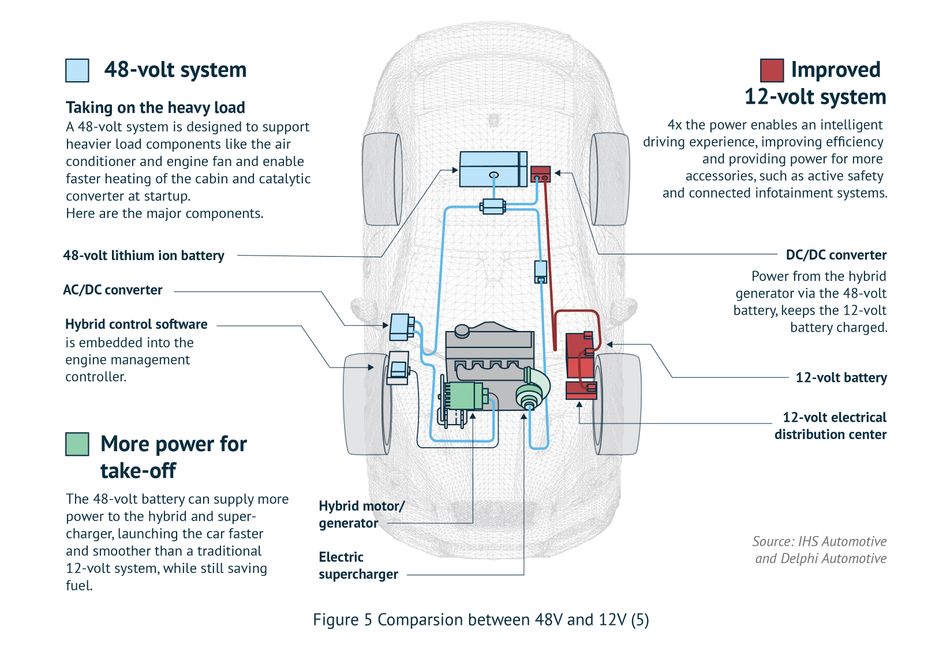

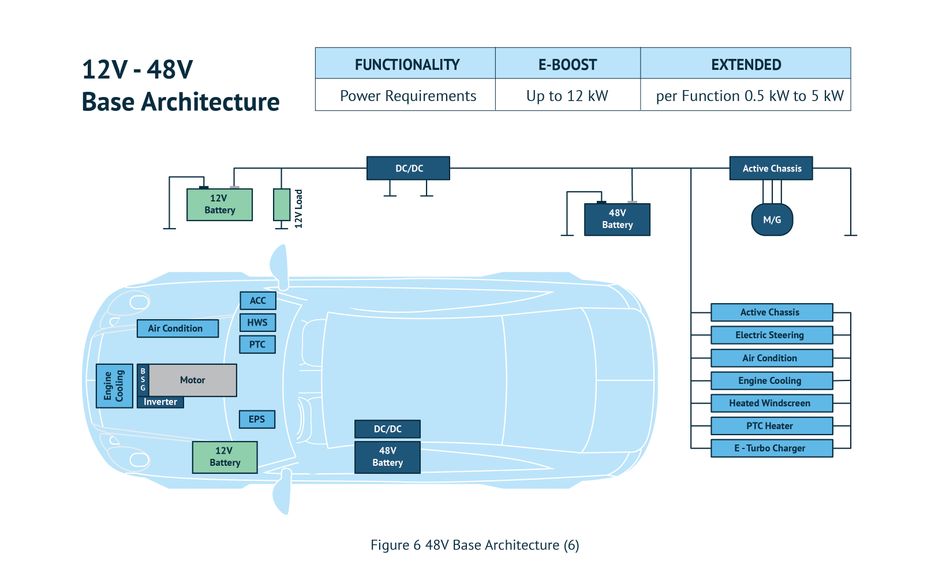

Current EVs are 12V systems, and they reduce carbon dioxide, carbon monoxide, nitric oxide, and particulate matter exhaust emissions substantially[4]. Engine-driven functions must convert to electric motor control to achieve this emissions improvement. Compared to the traditional 12V, the 48V architecture was developed to achieve emission criteria. Besides this property, 48V takes higher loads, especially when energy consumption features such as air conditioning are activated (see Figure 5).

By Ohm’s Law, 48V enables higher currents for the same resistance, providing more power for additional features. Power loss is proportional to the square of current in Joule’s Law, meaning that the 48V battery reduces resistive losses over the 12V system. This result increases the number of motor-control features engineers can include on the same bus, improving the user experience. The success of installing a 48V battery that enables higher power density cand provides efficient power, smoother acceleration, increased capacity for electrically powered motors, and protects packaging space for additional system controls and features.

DC motor speed is directly related to voltage and inversely proportional to current. Because 12V motors run at higher current because of Ohm’s Law, they operate at higher speeds than 48V. The higher current of 12V typically results in design engineers rating them for lighter-duty applications than 48V. A great feature about 48V batteries is that the 12V Battery does not need to be removed. To prevent overloading the motor, a 48V system can be connected to the 12V system. It will just operate at a slower speed. This can be possibly done via DC-DC converter (Figure 6).

Control Methods

Motor control has some fundamental differences between electric and internal combustion vehicles. Unlike the combustion engine, which provides a constant load to the system, electric motors give only on-demand power. This difference enables electric motors to avoid introducing constant load into the system. Electric motors control speed and performance by varying the applied voltage and current, though the inefficiency associated with this approach often cannot deliver enough torque. Torque and speed control are fundamental to ensure the motor performs long enough without incurring damages and increase reliability [7].

Some standard control opportunities include driver communication features, diagnostics, regenerative braking, and power management. These use cases encourage the control strategy to promote customization for the user by tailoring the experience to his personal preference and improving the motor’s efficiency by recovering energy from braking and managing power.

To improve control, design engineers use electronic switches to reduce voltage and current instantly. This approach still carries static resistive (IR) losses and dynamic (transition) losses through on-off cycles. The design objective for these switches is to minimize these loss mechanisms. As with the 48V bus, increasing voltage (and current in turn) can reduce loss. But total control can become a challenge considering that EV applications are built to operate in high-performance circumstances in which the motor should receive the expected transient response [7].

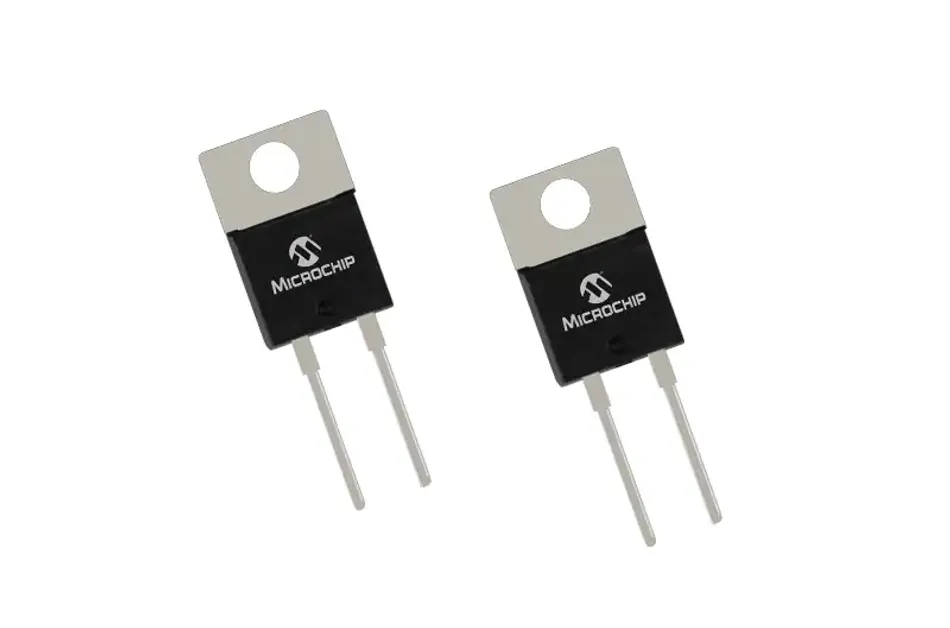

Either silicon carbide (SiC) or gallium nitride (GaN), higher-voltage switches are more complex to design, but they provide an opportunity for innovation. Both options are a compelling solution to offset the physical limits imposed by complex EVs on devices such as silicon-based power metal-oxide semiconductors field-effect transistors (MOSFETs) and silicon insulated gate bipolar transistors (IGBT). This chemistry offers higher critical breakdown voltage, thermal conductivity, and melting point than its silicon-based predecessor, making SiC better for high-temperature applications and 3 to 4 times more capacity for thermal conductivity than GaN. These improvements enable thinner material and a broader band gap to be used, reducing conductive resistance and leakage losses. Higher temperature operation also reduces the need for cooling throughout the system, reducing overall complexity and cost [8].

Conclusion

As evidenced in the 48V bus application, adopting a control strategy for higher-voltage operation improves performance, wastes less energy, and creates a better user experience overall. 48V can work as an extension of 12V and is the future of EVs. Overall, SiC MOSFETs are a perfect match for EVs in regular operability conditions as well as on rides where extensive use of components is required. High critical field and thermal conductivity make the SiC an attractive solution that is partly offered by its increased monotonic performance.

This article was initially published by Mouser and Microchip in an e-magazine. It has been substantially edited by the Wevolver team and sustainability engineer Nicolas Sarmiento Sierra. It's the fourth article of a 5-part series exploring the future of mobility. Future articles will examine the cybersecurity concerns in connected vehicles, discuss solutions for fast charging, and dive into how ethernet can deliver optimum data networks.

The first article looked at software control.

The second article examined cybersecurity concerns in connected vehicles

The third article surveyed the potential of automotive ethernet

About the sponsor: Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 1,100 manufacturer brands. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.

References

1. David Fuller. Fuel Pump Tech: Brushed vs. Brushless DC Motors [Internet]. 2016 [cited 2021 Jun 16]. Available from: https://www.onallcylinders.com/2016/08/11/fuel-pump-tech-brushed-vs-brushless-dc-motors/

2. Corporation NT. Automotive Motors [Internet]. 2021 [cited 2021 Jun 16]. Available from: https://nmbtc.com/automotive-motors/

3. Morris C. Next-generation switched reluctance motor uses no rare earth elements [Internet]. Charged Electric Vehicles Magazine. 2015 [cited 2021 Jun 16]. Available from: https://chargedevs.com/newswire/next-generation-switched-reluctance-motor-uses-no-rare-earth-elements/

4. Bai S, Liu C. Overview of energy harvesting and emission reduction technologies in hybrid electric vehicles. Renew Sustain Energy Rev [Internet]. 2021;147(October 2020):111188. Available from: https://doi.org/10.1016/j.rser.2021.111188

5. Bill Schweber. Motor Control [Internet]. Mouser Applications and Technologies. [cited 2021 Jun 16]. Available from: https://www.mouser.de/applications/adding-48V-to-12V-means-major-benefits/

6. Kumawat AK, Thakur AK. A Comprehensive Study of Automotive 48-Volt Technology. Int J Mech Eng. 2017;4(5):13–20.

7. Quintero-Manríquez E, Sanchez EN, Antonio-Toledo ME, Muñoz F. Neural control of an induction motor with regenerative braking as electric vehicle architecture. Eng Appl Artif Intell [Internet]. 2021;104(July 2020):104275. Available from: https://doi.org/10.1016/j.engappai.2021.104275

8. Ngwashi DK, Phung LV. Recent review on failures in silicon carbide power MOSFETs. Microelectron Reliab. 2021;123(February):114169.