What Is An NTC Thermistor: A Guide to This Temperature-Sensitive Resistor

Have you ever wondered how your car’s engine manages to stay efficient or how your smartphone prevents overheating? Behind these feats lies the NTC thermistor. This article will explore NTC Thermistor’s working principles, characteristics, applications, and challenges.

Introduction

In today’s world, keeping track of temperature is more important than ever. From protecting your phone’s battery to controlling factory machines, accurate temperature measurement is essential. This is where NTC thermistors stand out. They can detect even small temperature changes and are used in everything from automotive systems to consumer electronics and more.

NTC thermistors were developed to solve the growing need for better temperature monitoring [1]. Over time, they’ve become key components in many industries because of their ability to respond quickly and accurately to changes in temperature. You’ll find them in cars, laptops, and even industrial machines, helping ensure everything runs smoothly.

In this article, we’ll break down what an NTC thermistor is, how it works, its features, and where it’s used. By the end, you’ll see why this small but powerful temperature sensor is so important in modern technology.

Understanding NTC Thermistors

What Defines an NTC Thermistor?

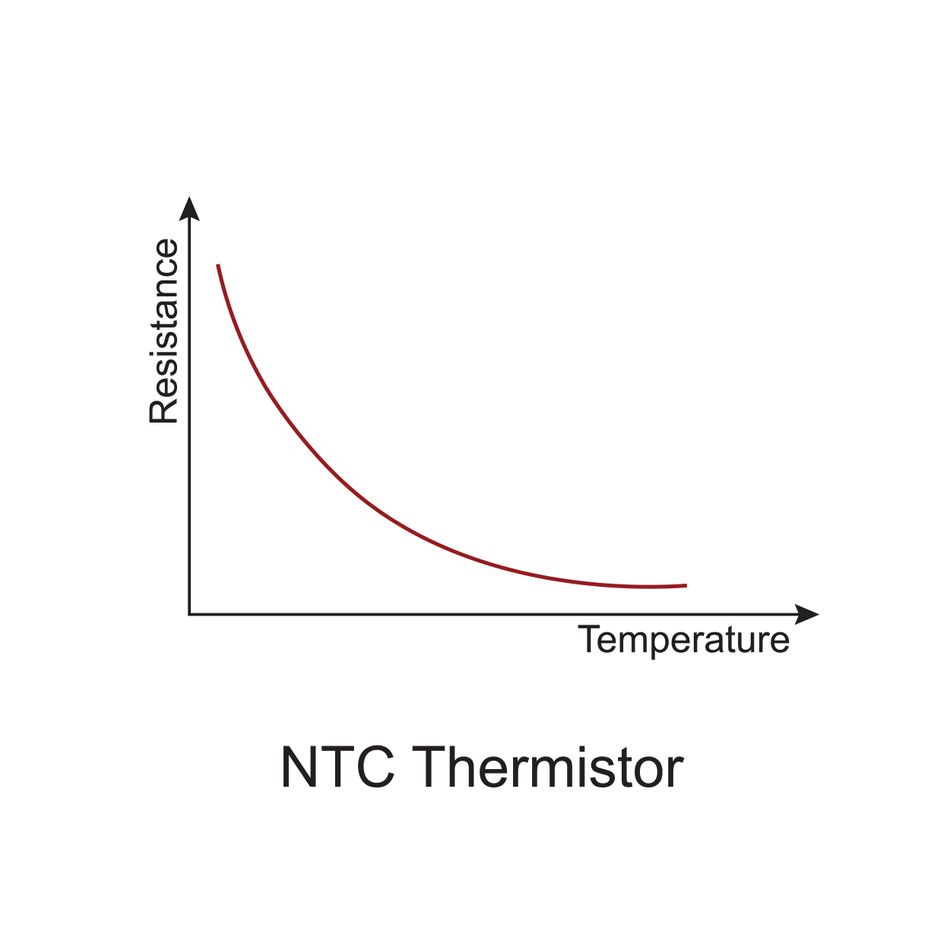

An NTC thermistor is a type of resistor whose resistance decreases as temperature increases. This unique property, known as the negative temperature coefficient, enables the thermistor to accurately measure and respond to temperature changes.

Unlike other temperature sensors like RTDs (Resistance Temperature Detectors) or PTC thermistors (Positive Temperature Coefficient thermistors), NTC thermistors are highly sensitive to small temperature changes, particularly at lower ranges. While RTDs offer extreme accuracy, they are more expensive and slower to respond. On the other hand, PTC thermistors, which increase resistance with rising temperature, are typically used in applications like overcurrent protection rather than temperature monitoring.

Let’s discuss a few characteristics of NTC Thermistors in brief:

- High Sensitivity: NTC thermistors can detect minute temperature changes due to their rapid resistance variation. This sensitivity is particularly beneficial in medical devices, such as digital thermometers, where accurate and quick temperature readings are critical for patient care.

- Wide Temperature Range: They operate effectively across a broad range of temperatures, making them suitable for diverse applications.

- Compact Size: Their small form factor allows integration into modern, space-constrained devices.

- Cost-Effective: Compared to other temperature sensors, they are affordable and provide reliable performance

Types of Thermistors

Thermistors, or temperature-sensitive resistors, are primarily divided into two types: NTC (Negative Temperature Coefficient) and PTC (Positive Temperature Coefficient) thermistors. These types differ in how their resistance changes with temperature, making them suitable for different applications.

NTC Thermistors

NTC thermistors are the most widely used and have a negative temperature coefficient, meaning their resistance decreases as temperature increases. This characteristic makes them ideal for applications that require precise temperature measurement and control, such as in automotive systems, consumer electronics, and industrial processes. For example, NTC thermistors are used to monitor battery temperature in smartphones or engine temperature in cars due to their accuracy and sensitivity. There are also different types of NTC thermistors utilized based on their applications [2].

PTC Thermistors

PTC thermistors, on the other hand, have a positive temperature coefficient, meaning their resistance increases as temperature rises. They are commonly used as current limiters or self-regulating heating elements. For instance, PTC thermistors are often found in circuit protection applications, where they prevent overheating by limiting current flow when temperatures exceed safe limits.

The key difference lies in their resistance behavior: NTC thermistors are best for temperature sensing and monitoring, while PTC thermistors excel in overcurrent protection and self-heating applications. Understanding these distinctions helps engineers choose the right thermistor for specific needs.

Recommended Readings: Thermistor vs Thermocouple: Which Temperature Sensor Suits Your Engineering Needs?

How NTC Thermistors Work

The functioning of an NTC thermistor is rooted in its unique material properties. These thermistors are typically made from semiconductors such as metal oxides (e.g., manganese, nickel, or cobalt), which exhibit a negative temperature coefficient. As the temperature of the thermistor increases, the resistance value decreases, a behavior caused by the heightened activity of charge carriers—electrons and holes—at higher temperatures.

When an NTC thermistor is connected to a power supply, it generates heat due to the flow of current. This phenomenon, known as self-heating, results in further resistance reduction, creating a feedback loop. While this thermal behavior is advantageous for applications like inrush current limiting, it must be managed in sensitive systems where precise temperature measurement is critical [3][4].

Engineers often rely on thermistor probes to prevent inaccuracies caused by self-heating, which minimize thermal effects by separating the thermistor from the heat source. Additionally, factors like ambient temperature and operating temperature range must be carefully considered to ensure the thermistor operates within its specified limits as provided in the datasheet.

This intricate balance of thermal dynamics, material properties, and circuit design highlights why NTC thermistors are a preferred choice for accurate, proportional, and efficient temperature sensing in both analog and digital systems.

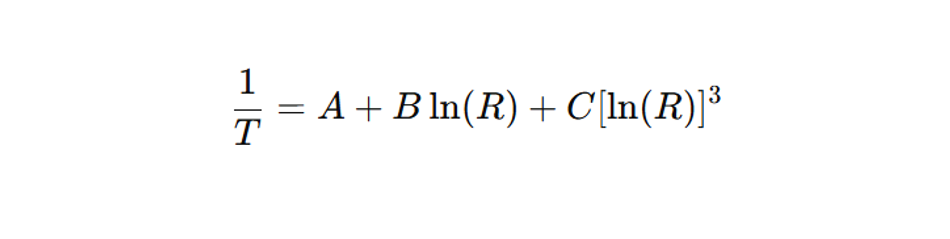

The relationship between resistance and temperature can be mathematically expressed using the Steinhart-Hart equation, which allows precise temperature calculations by correlating the thermistor's resistance with its temperature t in Kelvin.

This diagram shows how resistance decreases as temperature increases in an NTC thermistor, making it easier to understand their behavior in practical applications.

For example, in an automotive application, an NTC thermistor might monitor the coolant temperature in an engine. As the coolant heats up, the thermistor detects the temperature change and sends a signal to the control unit, ensuring the engine operates efficiently and safely.

Factors influencing performance include:

- Material Composition: Different ceramic or metal oxide formulations affect sensitivity and resistance range.

- Size: Smaller thermistors have faster response times but may have lower power-handling capabilities.

- Encapsulation: Protective coatings can enhance durability in harsh environments, impacting accuracy and response time.

Coder’s Corner: Interfacing NTC Thermistor with Arduino

Key Characteristics of NTC Thermistors

NTC thermistors are renowned for their exceptional properties, which make them invaluable in numerous applications [5]:

Steinhart–Hart Equation

The Steinhart–Hart equation is a widely used formula for calculating the temperature of an NTC thermistor based on its resistance. This equation provides an accurate relationship between the resistance value of the thermistor and its temperature t in Kelvin:

Where:

- T is the absolute temperature in Kelvin.

- 𝑅 is the resistance of the thermistor.

- A, 𝐵, and 𝐶 are coefficients specific to the thermistor, typically provided in the datasheet.

The Steinhart–Hart equation is especially valuable for applications requiring precise temperature measurement across a broad operating temperature range, as it accounts for the non-linear behavior of NTC thermistors.

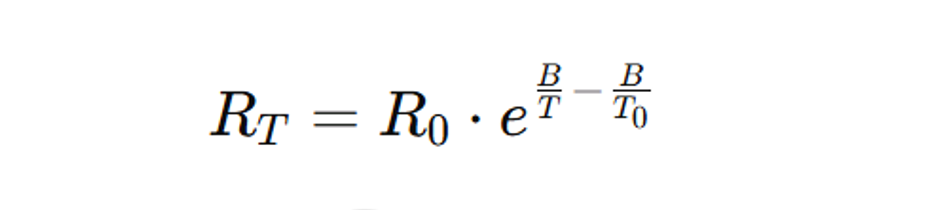

B or β Parameter Equation

- 𝑅𝑇 is the resistance at temperature T (in Kelvin).

- 𝑅0 is the resistance at a reference temperature. 𝑇0 (commonly 25°C or 298.15 K).

- B (or β) is the thermistor’s characteristic constant, typically found in the datasheet.

This equation is simpler than the Steinhart–Hart equation but less accurate at extreme temperatures. It is ideal for estimating resistance values in systems with well-defined ambient temperature or operating temperature constraints.

- Accuracy: NTC thermistors provide precise temperature readings, making them ideal for applications where exact measurements are crucial. They exhibit a consistent and predictable resistance-temperature relationship.

- Wide Operating Range: These thermistors operate effectively across a wide temperature spectrum, from cryogenic temperatures to high-temperature environments, ensuring versatility in diverse conditions, From as low as -50°C to over 150°C, depending on their material composition and design.

- Stability: With excellent long-term reliability and minimal drift in resistance, NTC thermistors maintain their performance over prolonged periods, even under challenging conditions.

- Temperature Sensitivity: The steep resistance-temperature curve of an NTC thermistor allows for high sensitivity, enabling precise temperature compensation in electronic circuits.

- Material Composition: The use of semiconductor oxides (e.g., manganese, nickel, or cobalt) gives NTC thermistors their unique properties. These materials are often coated with epoxy for insulation and durability, ensuring resistance to environmental factors like moisture and mechanical stress.

- Fast Response Time: NTC thermistors exhibit a quick response time to temperature changes, enabling near-instantaneous readings in dynamic environments. The time constant of the thermistor determines how quickly it reacts to ambient changes, critical in applications like HVAC systems and process control.

| Property | NTC Thermistors | Other Thermistors |

| Accuracy | High | Moderate |

| Temperature Range | Broad (-55°C to 200°C) | Narrower (-20°C to 100°C) |

| Stability | Excellent | Variable |

| Cost | Cost-effective | Varies by type |

Applications of NTC Thermistors

NTC Thermistors in Consumer Electronics

NTC thermistors play a vital role in many household devices, where they ensure efficient and accurate temperature control. Here are some key examples of their applications [6][7][8]:

Thermostats: Used to detect room temperature and regulate heating and cooling systems.

Battery Management Systems: Monitor and manage battery temperatures to prevent overheating and enhance battery life.

Refrigerators and Freezers: Ensure precise temperature maintenance to keep food fresh.

Ovens and Microwaves: Help maintain consistent internal temperatures for optimal cooking performance.

Washing Machines and Dryers: Regulate water and air temperatures to improve efficiency and prevent damage to clothing.

+--------+ +--------+ | Power |-------| NTC |------+ | Supply | | Sensor | | +--------+ +--------+ | | | +--------Control Unit------+

This ASCII diagram represents a simple placement of an NTC thermistor in a household device circuit, connected to a control unit for temperature monitoring.

Role in Industrial Systems

NTC thermistors are critical components in manufacturing and industrial processes, providing reliable temperature monitoring and control. Their ability to respond rapidly to temperature changes ensures efficiency and safety in industrial applications.

Temperature Control in Motors: NTC thermistors are used to monitor motor temperatures, preventing overheating and ensuring optimal performance in heavy machinery.

HVAC Systems: They help regulate and maintain precise temperature levels in heating, ventilation, and air conditioning systems, improving energy efficiency and comfort.

Industrial Equipment Monitoring: These thermistors are embedded in equipment to monitor operational temperatures, reducing downtime and avoiding damage due to overheating.

| Industrial Application | Benefits |

| Motors | Prevents overheating, prolongs lifespan |

| HVAC Systems | Enhances energy efficiency |

| Industrial Equipment | Ensures operational reliability |

Challenges When Using NTC Thermistors

Environmental Factors

Environmental conditions can significantly affect the performance and reliability of NTC thermistors, especially in industries like automotive or aerospace where precise temperature control is critical for safety and functionality. Factors such as humidity and extreme temperatures can introduce challenges that impact their functionality:

- Humidity: Prolonged exposure to high humidity can cause moisture ingress, leading to changes in resistance and reduced accuracy.

- Extreme Temperatures: Operating beyond the specified temperature range can result in permanent damage to the thermistor or unstable readings.

- Thermal Cycling: Repeated exposure to rapid temperature changes may lead to physical stress and eventual degradation of the thermistor.

Mitigation strategies include:

- Encapsulating the thermistor in moisture-resistant materials to prevent water absorption.

- Using thermistors rated for a wider temperature range for applications with extreme thermal conditions.

- Implementing thermal buffers or heat sinks to minimize the effects of rapid temperature fluctuations.

Suggested Readings: Using the IoT to create a greener future for smart cities

Technical Limitations

NTC thermistors, despite their versatility, have inherent limitations that must be considered during their application:

- Non-Linear Resistance-Temperature Characteristics: The resistance-temperature relationship is not linear, making it challenging to achieve precise calculations over a broad temperature range without complex algorithms or calibration.

- Self-Heating Effects: When current flows through the thermistor, it generates heat, which can alter its resistance and lead to measurement inaccuracies.

- Limited Temperature Tolerance: NTC thermistors are typically sensitive to temperatures outside their specified operating range, risking damage or failure [10].

| Limitation | Challenge | Potential Workaround |

| Non-linear Characteristics | Complex calibration needed [9] | Use dedicated linearization circuits or software |

| Self-Heating Effects | Measurement inaccuracies | Limit current flow through the thermistor |

| Limited Temperature Tolerance | Risk of damage outside operating range | Choose thermistors with a wider temperature range |

Table of Contents

IntroductionUnderstanding NTC ThermistorsWhat Defines an NTC Thermistor?Types of ThermistorsHow NTC Thermistors WorkKey Characteristics of NTC ThermistorsSteinhart–Hart EquationB or β Parameter EquationApplications of NTC ThermistorsNTC Thermistors in Consumer ElectronicsRole in Industrial SystemsChallenges When Using NTC ThermistorsEnvironmental FactorsTechnical Limitations