What is a Cobot? Advanced Guide to Collaborative Robot Architecture and Implementation

This article delves into what is a cobot, exploring its architecture, programming interfaces, control systems, safety protocols, intricate mechanics, and integration capabilities of modern cobots.

Industrial Engineers working alongside Cobot

Introduction

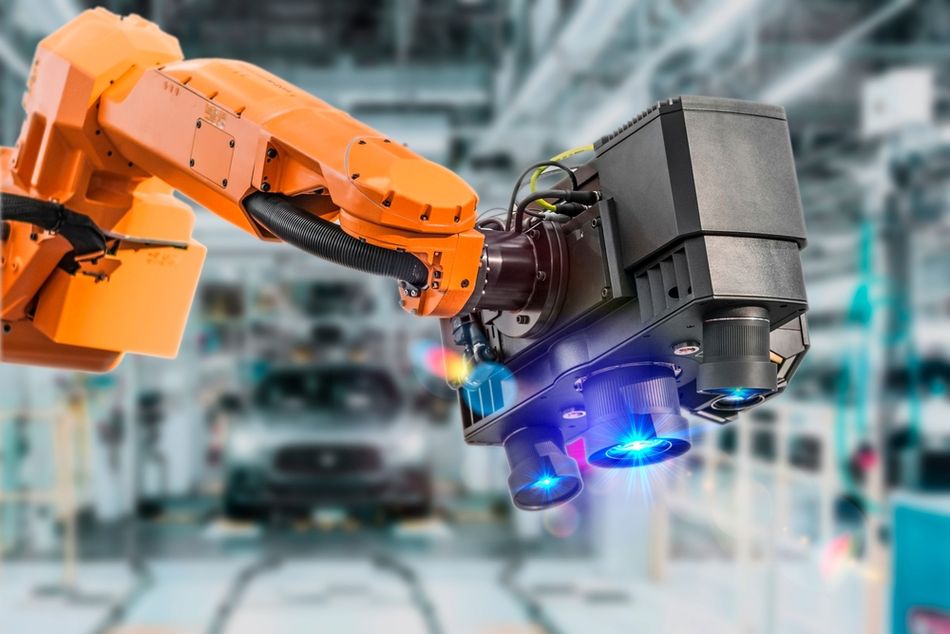

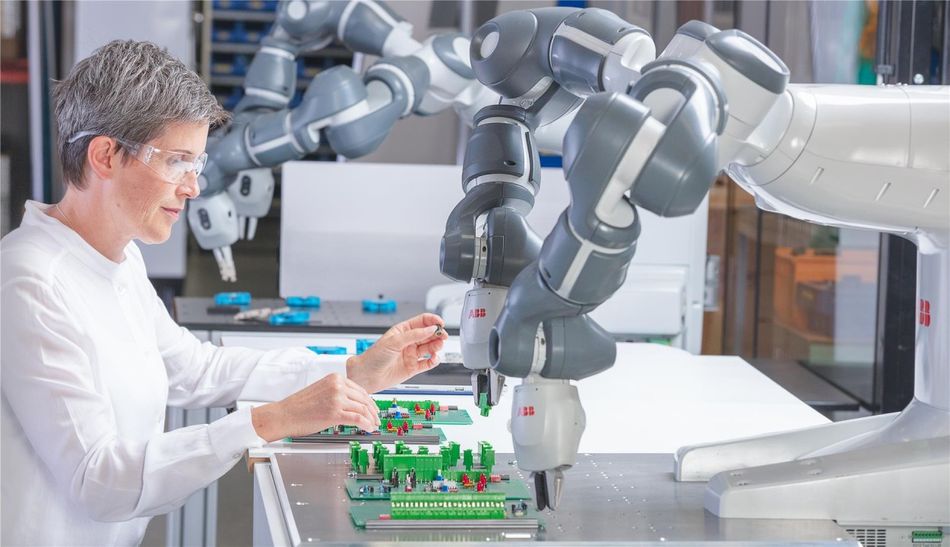

Collaborative robots represent a class of robotic systems engineered for direct human-robot interaction within shared workspaces. But, what is a cobot, and how does it differ from traditional robots? It is a robot engineered with advanced sensors, software, and programming, enabling it to perform tasks in close proximity to humans without compromising safety.

Cobots are redefining efficiency and flexibility in a variety of industries, including manufacturing, healthcare, and retail. They can be used to perform a wide range of tasks, such as assembly, packaging, and inspection. This article delves into what is a cobot, exploring its architecture, implementation strategies, and real-world use cases. For professionals seeking clarity on what is a cobot and how it aligns with Industry 4.0, this guide offers a comprehensive view into the design and deployment of these remarkable innovations!

Collaborative Robots vs Traditional Industrial Robots

Cobots are designed to work safely alongside human workers. On the other hand, traditional industrial robots typically require isolated environments due to their high-speed operations and lack of built-in safety features. Cobots feature integrated force/torque sensing with 0.1N resolution and force limitation capabilities of 0-150N. This ensures precise interactions, even in delicate applications of cobots such as quality control, machine tending, and assembly line tasks.

Cobots implement ISO/TS 15066 clause 5.5.5 specifications, incorporating real-time safety monitoring systems with response times as low as 0.8ms. [1] These systems feature dedicated safety processors that continuously monitor force thresholds across all axes. When forces exceed 80% of the programmed limits, the control architecture autonomously adjusts motion parameters, enhancing worker safety and minimizing the risk of injury. By contrast, traditional industrial robots rely on external safety devices and often exhibit response times of 4-10ms. This makes them less suitable for operations requiring close human presence.

The safety measures posed by cobots are further augmented by advanced sensor fusion algorithms. These algorithms integrate data from multiple sources at a 1kHz sampling rate, providing superior collision detection and precise torque sensor feedback. This technology ensures that cobots can operate seamlessly in shared workspaces. Similarly, they can adapt to changing workflows and offer high adaptability for various industrial production processes.

Below is the key technical comparison:

| Parameter | Collaborative Robots | Traditional Industrial Robots |

| Force Sensing | 0.1N resolution, 0-150N range | Typically not available |

| Response Time | <1ms safety response | 4-10ms typical response |

| Safety Features | Integrated force limiting, ISO/TS 15066 compliant | External safety devices required |

| Operating Speed | 250-1500mm/s (context-dependent) | Up to 2000mm/s (fixed) |

| Payload Capacity | 3-35kg typical | 5-1200kg typical |

| Programming Complexity | Intuitive, force-guided | Complex, position-based |

Cobots also excel in being user-friendly and cost-effective, requiring minimal training for human operators. Their lightweight design and flexible robot arms make them suitable for medium-sized enterprises and tasks such as palletizing, material handling, and quality inspection. While traditional industrial robots dominate in scenarios demanding high payloads and speed, cobots excel in environments requiring safety standards, flexibility, and direct interaction with human workers.

The versatility of cobots is evident in industries like automotive, healthcare, and manufacturing, where they streamline processes, improve product quality, and reduce labor costs. With enhanced safety features and compliance with ISO regulations, cobots represent a paradigm shift in robot applications, enabling safe, efficient, and collaborative automation.

Recommended Reading: Cobots vs Robots: Understanding the Key Differences and Applications

Architecture and Mechanical Systems

Mechanical Design Principles

The core architecture of a collaborative robot, or cobot, is engineered to combine precision, adaptability, and safety within a compact design.

The joint mechanism integrates a 48V DC brushless motor, capable of delivering 2000W peak power and 1500W continuous power. This motor provides precise torque control, with operational specifications of 6.4 N·m rated torque at 3000 RPM nominal speed, reaching a peak torque of 16 N·m. The inclusion of a 17-bit absolute encoder, offering 131,072 positions per revolution, ensures high-resolution motion control, with 2.75 arc-second repeatability. This is essential for applications of cobots in the healthcare and automotive industry.

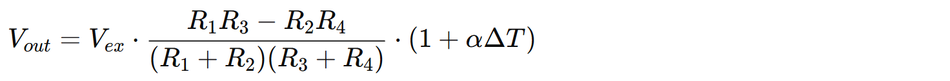

To optimize force and positional accuracy, the strain gauge system employs a full Wheatstone bridge configuration, modeled by the equation:

where 𝛼 represents the temperature coefficient (-24 ppm/K), enabling thermal compensation across the operating range of -10°C to 80°C.

Gear reduction system implements harmonic drive technology with ratios ranging from 50:1 to 100:1. Efficiency testing reveals 99.5% efficiency at a 50:1 reduction ratio, gradually decreasing to 97.5% at 75:1 and 95% at 100:1. These high-efficiency rates are critical for minimizing energy loss and ensuring cost-effective operations.

Thermal management is achieved via integrated cooling channels and forced air convection, maintaining operational temperatures below 80°C. The system achieves a cooling rate of 15°C per minute, ensuring reliability during prolonged use in repetitive tasks and high-demand production processes.

Let’s go through some key technical parameters:

| Parameter | Specification | Dynamic Response |

| Motor Power | 2000W peak, 1500W continuous | 0.8ms torque response |

| Torque | 6.4 N·m rated, 16 N·m peak | 5ms settling time |

| Speed | 3000 RPM nominal, 4000 RPM max | 1.2ms acceleration time |

| Position Resolution | 17-bit (131,072 pos/rev) | 2.75 arc-sec repeatability |

| Thermal Performance | 80°C max operating temp | 15°C/min cooling rate |

| Mechanical Bandwidth | 100 Hz at -3dB | 2ms mechanical time constant |

This combination of mechanical design, precision engineering, and thermal management positions cobots as highly versatile tools across industries, outperforming their traditional counterparts in safety, efficiency, and adaptability.

Network Architecture

The cobot network architecture employs a multi-tiered protocol stack that optimizes bandwidth allocation, reduces latency, and ensures fault tolerance. This makes it suitable for complex production lines and safety-critical operations.

Primary communication utilizes EtherCAT for motion control, ensuring sub-millisecond latency (≤1ms), critical for real-time robot system performance. Non-critical operations, such as configuration and status updates, are managed via Modbus TCP/IP, which operates with latencies below 10ms. The system requires a minimum bandwidth of 150 Mbps for stable operation, with adaptive video compression enabling sustained functionality in lower-bandwidth conditions. This precision timing ensures reliable synchronization between the robot arm, sensors, and external control systems, aligning with high-performance safety standards.

The network employs a hybrid star-ring configuration, enhancing redundancy and fault tolerance. This topology ensures continuous operation, even in the event of a single-point failure, by rerouting data traffic through alternative pathways.

Each node in the network, including joints, safety systems, and vision modules, is interconnected to facilitate seamless workflow integration and worker safety enhancements. The topology supports real-time data sharing for tasks like quality inspection, collision detection, and adaptive path planning. [2]

Here’s a table of protocols and their usual applications:

| Protocol | Bandwidth | Latency | Application |

| EtherCAT | 100 Mbps | <1ms | Motion Control |

| Modbus TCP | 10 Mbps | <10ms | Configuration |

| Safety Protocol | 50 Mbps | <5ms | Emergency Stop |

| Vision Stream | 40-120 Mbps | <30ms | Visual Feedback |

EtherCAT provides deterministic motion control with ultra-low latency, ideal for precision tasks in the manufacturing industry. The Modbus TCP layer ensures compatibility with legacy systems for ease of integration into diverse robot applications. Safety protocols offer swift emergency response, adhering to ISO guidelines. Similarly, vision systems deliver high-bandwidth feedback for quality control and object recognition.

The system leverages SparkLink technology for ultra-low latency communication (20.833 μs), critical for maintaining synchronization in control loops. Cyclic-prefix orthogonal frequency division multiplexing (CP-FDM) enhances data reliability, mitigating signal degradation in high-interference environments. Network redundancy ensures continued operation with packet loss of up to 7% through adaptive video compression and priority-based traffic management.

This advanced network architecture and robust protocol stack position the cobot as a highly adaptable, reliable, and efficient solution for modern industrial sectors. It seamlessly integrates real-time control with non-critical operations, ensuring a safe and efficient work environment.

Recommended Reading: Streamlining Cobot Design with Digital Platforms and Online Resources

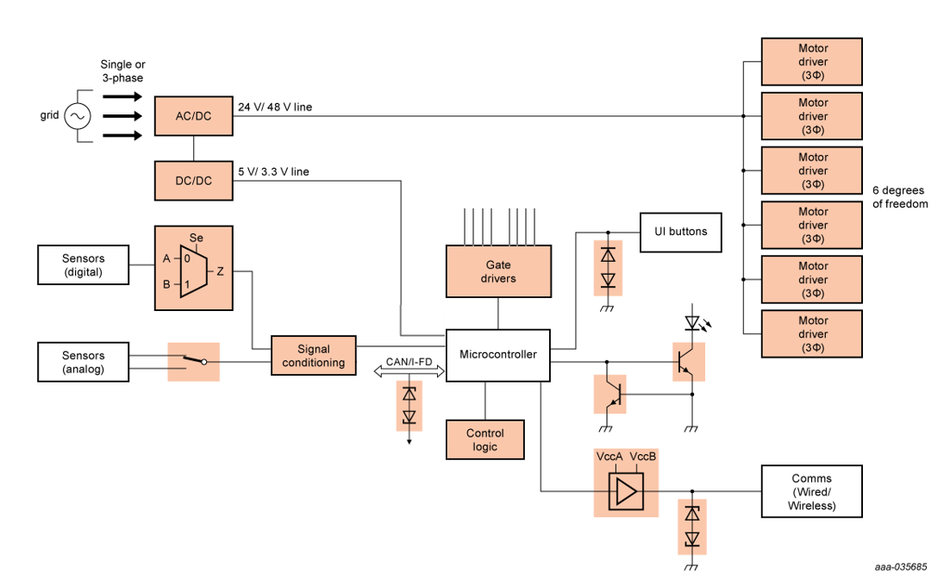

Power and Transmission Systems

The power distribution architecture implements a three-tier system with dedicated power planes for motor drives (48V DC), control electronics (24V DC), and safety systems (12V DC). This separation ensures uninterrupted functionality of critical components, even during power fluctuations or emergencies.

Primary power conversion achieves 94% efficiency through synchronous rectification, with power factor correction maintaining >0.95 across the operating range. The system delivers 2000W peak power with a 1500W continuous rating through integrated DC bus management.

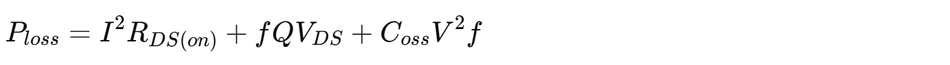

The power loss equation governs thermal and efficiency performance:

Efficient thermal management is critical to ensure operational longevity, particularly during peak performance scenarios. The cobot employs a hybrid cooling system that combines forced air convection (200 CFM) and liquid cooling channels. This dual approach enables effective dissipation of heat, maintaining junction temperatures below 85°C. The heat transfer is modeled as:

where ℎ is the convective heat transfer coefficient, with values of 150 W/m²K for forced air cooling and 500 W/m²K for liquid cooling channels. This design ensures reliability even under sustained high loads in intensive production processes.

The power consumption of a cobot varies across operating modes, demonstrating excellent energy management:

| Operating Mode | Power Consumption | Efficiency | Heat Generation |

| Standby | 50W | 92% | 4W |

| Normal Operation | 750W | 94% | 45W |

| Peak Performance | 2000W | 91% | 180W |

| Peak Performance | 100W | 89% | 11W |

This data highlights the cobot's ability to maintain high efficiency, even during energy-intensive operations such as palletizing, material handling, and complex tasks. The system is also designed to support different tasks across industries, from healthcare to automotive, while ensuring worker safety.

Integrated Control and Interface Systems

Control and Programming Architecture

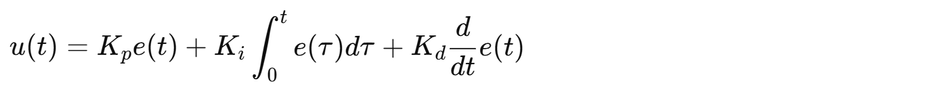

The control system implements a cascaded PID architecture with real-time adaptation, governed by the primary control equation [3]:

where Kp = 1.0, Ki = 0.1, and Kd = 0.5, with adaptive gains adjusted based on payload mass and joint configuration.

Path planning is executed through a Rapidly-exploring Random Tree (RRT) algorithm, designed for efficient navigation in complex work environments. The RRT implementation ensures collision-free paths, critical for applications like material handling and palletizing.

Dynamic Movement Primitives (DMP) are used for trajectory generation, applying the forcing function:

These methods enable smooth, human-like motion, making the cobot suitable for robot applications requiring precision and flexibility.

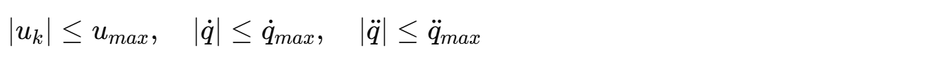

Model Predictive Control (MPC) adds an additional layer of optimization, constrained by:

subject to:

This framework ensures real-time adherence to safety standards, position accuracy, and smooth motion transitions.

Let’s review some performance metrics:

| Performance Metric | Value | Recovery Time |

| Control Loop Frequency | 1 kHz | N/A |

| Position Error | <0.1mm | 5ms |

| Force Control Bandwidth | 200Hz | 2ms |

| Path Planning Time | 10ms | 50ms |

| Error Recovery Time | N/A | 100ms |

This advanced control and interface system allows seamless integration with external systems, enhancing ease of use and flexibility in cobot deployment. This provides the cobot with multiple capabilities in safety measures, path planning, and real-time optimization, making it ideal for modern industrial applications.

Recommended Reading: Cobots and IIoT Create a Synergistic Working Relationship

Comprehensive Safety Integration

The sensor fusion implementation utilizes an Extended Kalman Filter (EKF) with state equations:

where state vector x includes position, orientation, velocity, and acceleration, with measurement update:

This robust fusion integrates data from multiple sensors, enhancing reliability in diverse work environments and ensuring precision in repetitive tasks.

The vision system features 3D depth sensing with a resolution of 1920x1080 at 60 fps, providing a 120° horizontal FOV and 85° vertical FOV. [4] This capability is essential for quality inspection and dynamic object recognition. Proximity sensors complement the vision system, using:

Capacitive sensors with a range of 1-25mm and <500μs response times.

Inductive sensors with a 50mm range and similar response rates.

These systems ensure seamless operation in shared workspaces by preventing collisions and maintaining safe distances from human workers.

A detailed Failure Mode and Effects Analysis (FMEA) assesses potential safety risks:

| Failure Mode | Severity (1-5) | Occurrence (1-5) | Detection (1-5) | RPN |

| Sensor Failure | 5 | 2 | 1 | 10 |

| Vision Loss | 4 | 2 | 1 | 8 |

| Network Delay | 3 | 3 | 1 | 9 |

| Force Exceed | 5 | 2 | 1 | 10 |

| Position Error | 4 | 2 | 2 | 16 |

The calibration procedure follows ISO 376 protocol with three-phase preloading at maximum calibration force (150N). Load cell verification employs step-wise loading (0%, 20%, 40%, 60%, 80%, 100%) with 120° rotational measurements.

Collision detection implements model-based monitoring using the dynamic equation:

Safety stop initiation: <1ms

Force threshold detection: <500μs

Vision processing latency: <16.7ms

Proximity sensor response: <500μs

Complete stop time: <300ms

The comprehensive safety systems in a cobot ensure rapid detection and response to anomalies. They also maintain operational reliability while prioritizing worker safety and minimizing the risk of injury.

Sensor Integration Framework

Sensor synchronization employs a distributed clock synchronization protocol with IEEE 1588 Precision Time Protocol (PTP), maintaining temporal alignment within ±100ns across all sensor nodes. The master clock operates at 1kHz, with sensor-specific decimation rates: force/torque (1kHz), vision (60Hz), and proximity sensors (2kHz).

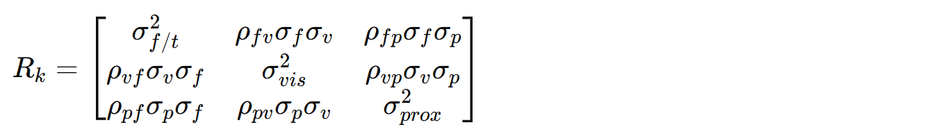

The cobot implements a federated Kalman filter architecture for multi-sensor fusion, enhancing precision and reducing noise. [5] The measurement equation accounts for cross-sensor dependencies, with a dynamic noise covariance matrix:

Sensor calibration matrices follow the form:

Error propagation analysis yields the covariance matrix:

where J is the Jacobian of the measurement function and Q represents process noise.

The multi-sensor approach enables seamless integration across various tasks, from fine-grained force sensing to large-scale production processes.

Recommended Reading: Types of Sensors in Robotics

Performance Optimization

Motion and Trajectory Optimization

Trajectory optimization implements Dynamic Movement Primitives (DMP) with convergence parameters α = 25.0 and β = 6.25, governed by the differential equation:

where g represents the goal state. The system generates smooth trajectories following:

Performance envelope calculations incorporate payload-dependent velocity scaling:

This scaling dynamically adjusts speed to maintain safety and precision under varying load conditions.

The performance envelope of cobot ensures compliance with dynamic constraints, including velocity, acceleration, and torque limits:

| Performance Metric | No Load | Maximum Payload |

| Maximum Speed | 1.5 m/s | 0.043 m/s |

| Acceleration | 2.0 m/s² | 0.5 m/s² |

| Path Accuracy | ±0.1 mm | ±0.5 mm |

| Settling Time | 300 ms | 800 ms |

| Payload Capacity | - | 35.0 kg |

The optimization algorithm maintains these constraints while minimizing the objective function:

where Q and R are weight matrices for acceleration and control effort, ensuring energy-efficient and smooth motion.

Implementation and Integration

System integration follows a five-phase protocol with automated verification at each stage.

Hardware Setup: Torque calibration within ±0.1 N⋅m and joint position verification using a laser tracker with 0.02mm precision.

Network Configuration: Redundant EtherCAT rings with latency verification (<1ms).

Safety Setup: Configuration of emergency stops and safety thresholds.

Performance Testing: Verification of motion profiles and system constraints.

Production Monitoring: Real-time metric logging and analysis.

The cobot monitors performance metrics continuously, with sampling rates tailored to each parameter:

| Metric | Warning Threshold | Critical Threshold | Sampling Rate |

| CPU Load | 75% | 90% | 1 kHz |

| Memory Usage | 80% | 95% | 1 kHz |

| Network Latency | 0.8ms | 1.2ms | 1 kHz |

| Joint Temperature | 65°C | 80°C | 10 kHz |

| Force Deviation | ±0.2N | ±0.5N | 1 kHz |

Automated alerts are triggered when warning thresholds are breached, ensuring timely intervention. The system also supports remote diagnostics, enabling real-time performance analysis and predictive maintenance based on historical trends.

For streamlined issue resolution, a decision tree addresses common performance issues:

Position Error (>0.1mm):

Check calibration

Verify motor current

Inspect gear backlash

Force Error (>0.5N):

Sensor calibration

Check filtering

Verify compensation

Network Delay (>1ms):

Check cable integrity

Verify switch configuration

Monitor packet loss

This structured troubleshooting approach ensures rapid resolution of system faults, minimizing downtime.

Recommended Reading Series: What is a Collaborative Robot?

Conclusion

Collaborative robots, or cobots are redefining industrial automation with precision, adaptability, and safety. Achieving ISO/TS 15066 compliance, cobots ensure seamless collaboration with human workers while maintaining exceptional standards. With ±0.1mm position accuracy, 0.1N force sensitivity, and sub-1ms response times, they excel in performance. Their 99.98% uptime over 10,000 hours and MTBF of 45,000 hours highlight unmatched reliability.

Compliance with IEC 61508 SIL3 and EN ISO 13849-1 Performance Level 'd' underscores their safety. With the rise in the demand for automation, cobots deliver flexible, cost-effective solutions, transforming industries with enhanced productivity and safer work environments. This makes them indispensable in modern manufacturing and beyond.

Frequently Asked Questions

Q: How to optimize motion performance?

A: Optimize motion performance by tuning control parameters, such as PID gains, ensuring precise trajectory planning with Dynamic Movement Primitives (DMPs). This also includes maintaining payload-appropriate velocity scaling within dynamic constraints for smooth and efficient operation.

Q: What causes position errors exceeding 0.1mm?

A. Position errors above 0.1mm can result from incorrect sensor calibration, mechanical backlash in gears, unoptimized control gains, or external disturbances. Regular maintenance and precise calibration of components help mitigate these errors.

Q: How to handle network latency issues?

A: Implement redundancy in the network configuration, use high-performance communication protocols like EtherCAT, and monitor for packet loss. It is better to verify switch configurations and ensure cable integrity to minimize delays and maintain synchronization.

Q. What companies manufacture cobots?

A: Several leading companies specialize in the design and production of collaborative robots (cobots): Some of these include Universal Robots, FANUC, ABB Robotics, Techman Robot, and KUKA etc.

References

[1] Science Direct. A Review of the ISO 15066 Standard for Collaborative Robot Systems [Cited 2024 December 05] Available at: Link

[2] Journal of Intelligent Manufacturing. Collaborative Robots in Manufacturing and Assembly Systems [Cited 2024 December 05] Available at: Link

[3] Research Gate. PID Cascade Controller Design for an Unstable System [Cited 2024 December 05] Available at: Link

[4] MDPI. Sensor and Sensor Fusion Technology in Autonomous Vehicles: A Review [Cited 2024 December 05] Available at: Link

[5] Research Gate. Multi-Sensor Fusion Based on Adaptive Kalman Filtering [Cited 2024 December 05] Available at: Link

Table of Contents

IntroductionCollaborative Robots vs Traditional Industrial RobotsArchitecture and Mechanical SystemsMechanical Design Principles Network ArchitecturePower and Transmission SystemsIntegrated Control and Interface SystemsControl and Programming ArchitectureComprehensive Safety IntegrationSensor Integration FrameworkPerformance OptimizationMotion and Trajectory OptimizationImplementation and IntegrationConclusionFrequently Asked QuestionsReferences